Submersible Sewage and Effluent Pump

Product Details:

Product Description

Submersible Sewage and Effluent Pump

Application of Sewage Submersible Pump

| Pumping Station | Untreated domestic sewage |

| Hotels, Subways, Airports | Faeces, Mixed liquor,Eatables, etc |

| Lifting station | Storm Water |

| Sewage works (treatment plant) | Grit trap pumps screened sewage, Raw Sludge, Activated Sludge Digested Sludge |

Technical Specifications

| Capacity | upto 1400 m3/hr |

| Head | 65 mtrs. |

| Solid size | upto 150 mm |

| H.P. | 1.5 to 200 HP |

Bearings :

The bearing arrangements with double angular Contact ball bearings with deep groove ball bearings give the Best resistance to the radial and thrust load combination in a centrifugal pump. The life rating is over 40000 hrs. The bearing are lubricated for life with a high temperature grease.

Dry, Squirrel cage 3 phase motor :

The housing is totally dust & waterproof for submersible duty.

The cooling is done externally and the special insulation of the winding takes care of rises in temperature during intermittent operations.

Cable Joint

Special triple protection does not permit any liquid entry into the dry motor.

Moisture detection probe

The moisture detector indicates any moisture penetration into the motor.

Thermal Motor Protection

Built-in temperature sensors enable tripping of the motor if the Temperature rises above 150 deg.C and restarts at 80 deg.C, giving complete dry run protection. Maximum permissible liquid temperature is 50 deg.C.

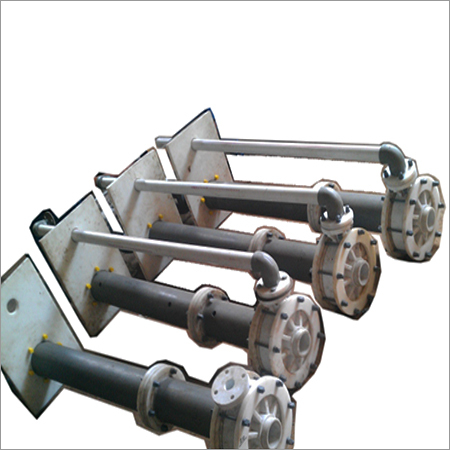

Guide Device with single / double guide rail

The guide rail system for lowering and lifting the pump is an outstanding feature. The pump slides down on to the duck foot bend and engages with it without bolting. It is not necessary to enter the sump to carry out inspection and maintenance work.

Profile Gasket :

Ensures flexible, pressure-tight and automatic connection between pump and duck foot bend

Double Mechanical Seals

All "Moniba" pumps have as standard equipment double mechanical seals which seal off the motor from the pump section. The seal has seal faces made from silicon carbide for long life. The design of the oil chamber ensures efficient cooling of the seals.

Shaft with rotor :

A shaft with a die-cast rotor on the motor side and a shaft protection sleeve on the pump side, ensures better life for the shaft. The compact seal arrangement has minimizes shaft over-hang and consequently minimizes shaft deflection. The motor portion is isolated from the pump by an intermediate casing with double mechanical seal in the oil chamber

OPEN SINGLE CHANNEL IMPELLER :

In order to achieve the best possible solids handling performance, the single channel impeller pumps are equipped with an open single channel impeller running against an adjustable suction cover.